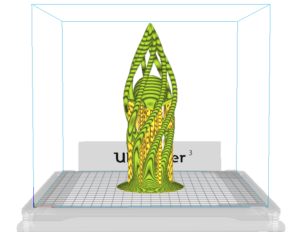

Model stats:

| Material volume: |

|

| Box volume: | sm3 |

| Surface area: | sm2 |

| Model weight: |

|

| Model dimensions: |

x x

cm

|

| Number of polygons: | |

| Number of figures: | |

| Common path: |

|

Online order details

Final cost including discount

will be available in the cart.

How to order 3D printing? Instructions!

Download several models.

Where download or create a 3D model?

-

Description

General information

In this manual, we will tell you how to order a product, since you are on the page of the automatic cost calculation system with the ability to place an order. Check your model carefully in the preview window. Check if the model matches REQUIREMENTS! If you did not find the necessary material or color in the automatic calculation system, this does not mean that we do not have it! We can select the material for your task individually in manual mode. If you require additional machining or paintwork, please additionally write to e-mail 3dprint@studia3d.com. Com.

Do you want the same calculator on your site? Follow the link!

How to place an order through the system?

1. Load the 3D model.

Models are stored on our server for 30 days from the date of download. Required 3D model format: .stl, .obj, .stp, .step, .igs, .iges,. The absence of Cyrillic in the model name is desirable. If you need to load several 3D models at once, you need to upload them to bulk upload page. Please note that if you load several models at the same time, the cost per batch may be reduced by completely Infill the 3D printer chamber. Then check the model in the program Netfabb or similar. Model must match polygon mesh requirements. Otherwise, the program will try to heal the model automatically, but there is a possibility that the model may be distorted. The maximum weight of a 50D model is 50 megabytes. Models of greater weight are calculated manually. If your XNUMXD model weighs more than XNUMX megabytes, it must be sent to us by mail 3dprint@studia3d.com. Com.

2. Select machine, material and parameters.

Each material has its own cost. If there are difficulties with the choice of material or you did not find the necessary material in the list of submitted materials, it is necessary to consult with specialists in the chat. Please note that if your model does not fit completely into the dimensions of the working field of the selected machine, you can break it into parts, and after printing, assemble it from its component parts. The calculation is made taking into account supporting material, which is included in the cost of XNUMXD printing. To ensure a rational calculation of the cost position the models correctly in the working area of the 3D printer. First of all, do not forget to indicate fill percentage... In other words, one of the most important parameters affecting both the cost and the strength of the product at the output.

3. Get a quote.

Please note that the calculation is considered preliminary! The price may vary slightly. As a result of this situation, you will receive a corresponding notification to the e-mail address specified during the ordering process. And although such situations are very rare, we cannot fail to notify you in advance. Payment orders can be made either by credit card or by invoicing for a legal entity. If the system is unable to automatically calculate the cost, you will see a price request form. As soon as the specialist calculates the model manually, you will receive a message to your e-mail.

4. Place your order and wait for readiness.

After paying for the order, your 3D models go to the production of our technologists, who, after checking the models, select the optimal technology for obtaining the product, the necessary modes of printing and post-printing processing. The result of the work of the technologist is the preparation of a control program for the equipment and the preparation of a production plan for the manufacture of your project, where your order is placed in line. After that comes the moment of production. Operators put your products into operation and make sure that the technology is not violated. After manufacturing, processing and packaging, your order is waiting at our office, pick-up point or leaves by courier.

Detailed instructions Prices for wholesale customers

Important! Work completion time: no more than 15 working days in accordance with terms of ordering... As a rule, the order is issued in 3-4 days. More details about the timing of production.

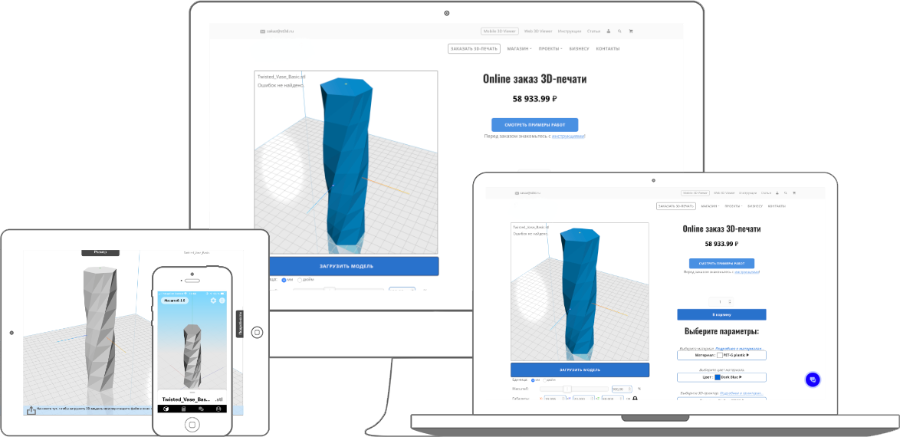

Place your order on the go

Take advantage of digital production directly from your smartphone! The application will allow you to view 3D models, the characteristics of the polygon mesh and place an order on the go! How to order on the app...

Share 3D model

Simple link

Link with parameters

The link is valid for 3 days. If you need to create permanent links, you need to subscription.

Checkout

Pay

Delivery

Warranty

-

More offersThere are no more offers for this item!

-

Questions

General questions

6 Questions

I downloaded the stl file of the 3D model of the case and wanted to know the cost of printing with Polyamide, I couldn’t find a price list with prices on your website -

Good afternoon.

The cost should appear automatically if you upload a 3D model on the page: https://studia3d.com/upload/

1. Download the 3D model, select the desired material, the system will show the cost if the 3D model matches requirements.

2. If for some reason the system does not show the cost of 3D printing of your model, please send a request by email 3dprint@studia3d.com.com

3. If you want to order 3D printing of a small series of products, you must proceed similarly to the second point.

Hello. Can I pay? -

Good afternoon. If you want to order 3D printing, then we can place an order and pay in any convenient way. All payment methods for the order are described on the page: https://studia3d.com/checkout/howtopay/

Help with the choice of material.

The part will be used as a master model for casting -

We recommend VisiJet as a solid master model. Please note that the ProJet 3D printer can also print with wax.

Find out the price, find out if there is a discount for the number of pieces. -

Good afternoon We have a volume discount. To understand the price, you need to send models and indicate the required number of products by mail 3dprint@studia3d.com.com

What is the thickness of one layer of printing?

3D printer: UlTi Steel 2 (FDM)

Fill: 50%

Material: ABS plastic (FDM)

White color -

The layer height in the automatic calculation system is always 0.2 mm for FDM technology. If you need a different layer height, please send a request with parameters to the mail 3dprint@studia3d.com.com

How quickly is the order delivered after payment? -

You can find information about production and delivery times page.